EU 2030 – Developing the circular economy into a location factor (DGAW, 20.6.2025, in German)

June 26, 2025

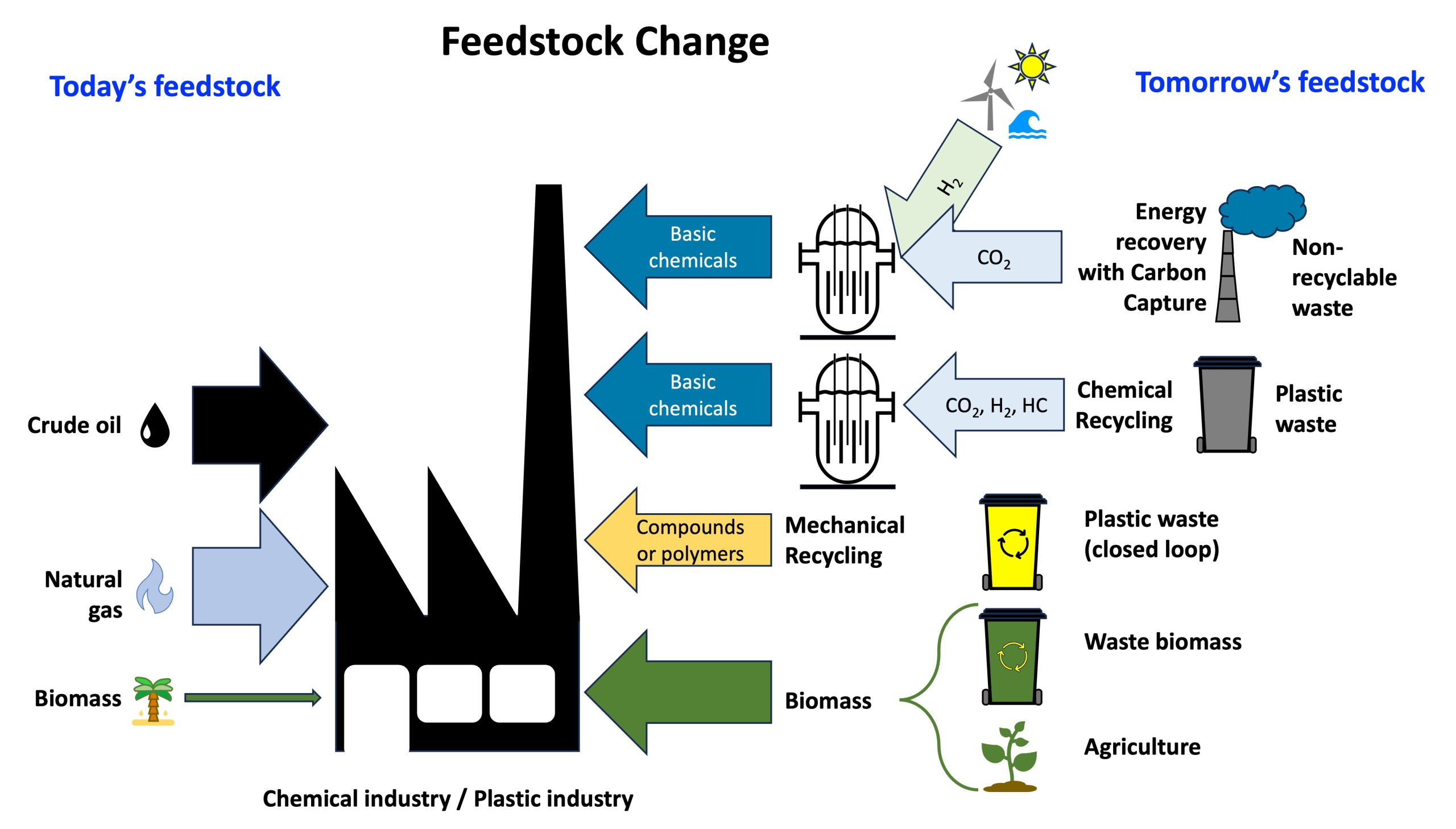

At the DGAW specialist event on 20.6.2025 in Berlin on the topic of EU 2030 – Developing the circular economy into a location factor, the contribution that the circular economy can make to defossilizing the use of raw materials in the chemical industry was discussed. In his introductory speech, Prof. Dr. Uwe Lahl presented the DGAW position paper EU 2030 – Developing the circular economy into a location factor. He pointed out that the technical and political debate on climate protection focuses too much on the defossilization of the energy sector. “What is missing is an understanding of the importance of substances and molecules for defossilization”.

A critical aspect of the defossilisation of the industry is the focus of legislation in Brussels, which on the one hand places far too much emphasis on the hydrogen path and at the same time over-regulates initial investments in the development of infrastructure. In the past, Germany has also focused one-sidedly on financial support for individual transformation projects (capex funding). Current developments show that it is politically easier to implement these subsidies. However, this is not enough because the framework conditions must also be created so that the defossilized products are competitive and are then also purchased. In contrast, the DGAW position paper calls for a smart policy mix for the necessary regulation, which on the one hand sets binding targets at the level of the individual companies, but on the other hand also promotes the creation of reliable markets for defossilized products.

The updated version of his presentation is now available for download.